ARBS WRAP 2024

ARBS 2024 was a resounding success for Blygold, where we showcased our latest innovations in HVAC maintenance and corrosion protection. Our booth buzzed with excitement as visitors experienced firsthand our commitment to enhancing system efficiency and longevity.

Highlights included a visit from Supercars leading driver Will Brown, who delighted visitors by autographing Blygold hats and posing for photos with them. Our competition to win the Blygold Bike was very popular with hundreds of entries received! Congratulations to David Gonzaga from Equilibrium Air Conditioning in Sydney for winning a flash new Blygold bike complete with wine carrier!

We engaged in insightful discussions with industry leaders, demonstrated the benefits of Blygold treatments and effectively presented each stage of our treatment process.

Thank you to everyone who visited us at ARBS 2024. We look forward to continuing to innovate and support your HVAC needs with excellence and expertise.

Blygold QLD

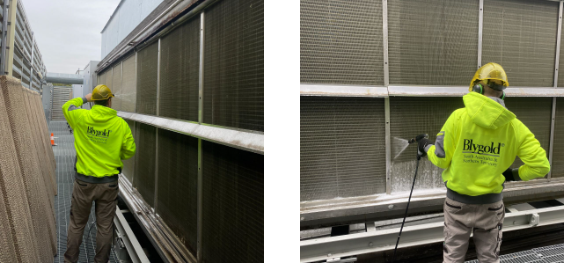

Blygold QLD has been extremely busy as of late, with an extensive amount of maintenance work, and a full workshop.

Highlighting the necessity of our maintenance plan, it’s crucial to recognize that corrosion isn’t confined to coastal regions; it can manifest anywhere.

Our skilled Blygold technicians conduct a comprehensive assessment of the coil, meticulously checking for corrosion and damage, straightening fins, and thoroughly cleaning both the coil and the unit inside and out.

For inquiries about our maintenance program, please don’t hesitate to reach out to Blygold Queensland today.

Blygold SA/NT

The SA-NT team are continuing the fight against corrosion well after coating application, prolonging asset life with both residential and commercial execution of an optimised Blygold Maintenance Program (BPM).

Removing environmental and airborne corrosive contamination is advantageous for both energy efficiency and longevity, keeping your Blygold coated system Blygold tough with a 12-month extended warranty.

Blygold NSW

After a long summer marked by wild rainy weather, it’s the perfect time to perform maintenance on your air conditioner’s coils as we head into the cooler season. This is an ideal opportunity to address any corrosion issues your clients may have and implement preventative measures to ensure the longevity of their assets.

Ensure that outdoor condenser coils are cleaned, undamaged, and free from debris. Clear away leaves and dirt around the unit, and trim back bushes and foliage near the condenser to minimize the risk of debris entering the unit during the cooler months.

Inspect the coil fins. Contractors know that the fins on an outdoor unit’s coils can sometimes become distorted, corroded, or damaged. We recommend using a fin comb to straighten the aluminium coil fins on both the condenser and evaporator portions of the air conditioner unit. If the fins are severely bent, corroded, or broken, discuss the issue with your client and address it by either replacing the coils and having them Blygold treated in our factory before reinstallation or having our trained applicators come on-site to professionally clean and apply Blygold coatings to ensure that your client receives the ultimate anti-corrosion treatment.

Additionally, please remember that we offer an on-site Blygold Maintenance Program (BMP), which we would be more than happy to provide a cost estimate for.

Blygold VIC/TAS

Blygold custom finishes to your indoor and outdoor air conditioning units

“It comes in any colour you like as long as it’s beige” If you’d prefer to coordinate the colour of your air conditioning equipment with your indoor and/or outdoor colour schemes, Blygold can help.

As well as providing market leading corrosion protection, Blygold’s polyurethane coatings for equipment casings can be custom coloured and finished anywhere from full matte to high gloss.

See below a few examples of our work. Please contact your local Blygold office for more information.

Blygold WA

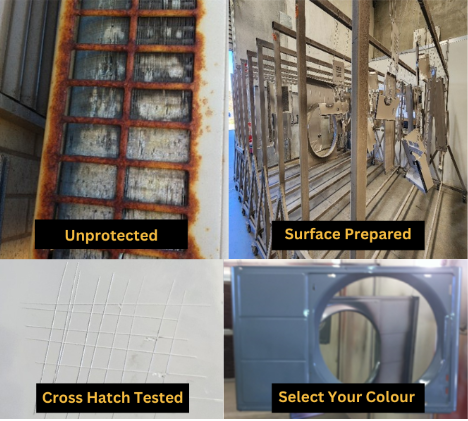

Condenser Cabinet Corrosion Protection – Adhesion directly linked to Surface Preparation

We have often been asked ‘why should condenser casings be treated and how?’ Most cabinets are made from Galvanised sheet metal with a powder coat top coat. Whilst a powder coat coating does provide some protection, there are very good and commercial reasons why you should consider additional protection.

Like most coatings, powder coat needs a flat surface to sit on and to adhere to. Coatings like liquids conform to the rules of cohesion which means coating droplets will migrate towards each other (away from sharp edges and on to flat surfaces) and or will split when applied to a sharp edge. This is evidenced by initial rust being seen on the very thin and sharp edges of casing panels and drilled holes. Combine this with the fact that base powder coat is porous, the end result will be corrosion will “spider” (travel under the powder coat) and pop up, by which time it’s too late.

Blygold WA use a 2-pack automotive polyurethane coating for casings and prior to its application a specific and specialised surface preparation protocol is followed to ensure true adhesion.

| FACT: Neither water based or thinner based paints will stick to powder coat without proper preparation |

The benefits of this protection are:

- Extended life of cabinets

- Extended aesthetic presentation

- Gives technicians a coating surface they can maintain

- Unlike Henry Ford – you can have any colour – including Black!

Blygold New Zealand

It was great to see all our customers at Build NZ last month. Xavier and Mark enjoyed engaging with everyone and presenting our latest advancements in HVAC maintenance and corrosion protection to New Zealand. The positive feedback and insightful conversations were truly inspiring. We appreciate your ongoing support and trust in our solutions. Looking ahead, we’re eager to continue serving you with excellence and innovation.

The Blygold Difference